A 100 watt Power Attenuator for up

to 2.5GHz

The testing of power transmitting

equipment requires some form of load to absorb the RF power generated in the

equipment , there are two types of load radiating & non radiating . The

Aerial is the normally " Radiating " load used, however if you wish

to measure the power safely without causing interference to other users a

" Non Radiating load " often called a " Dummy load " is

used.In order to measure the power out and any spurious signals I could have

used an " Inline " power meter and a sampling line ( Directional

Coupler ) to couple the transmitted signal into a spectrum analyser ,however

this means that the " sampled " signal would have different values of

coupling at different frequencies making the measurement of harmonics etc more

difficult so the use of a power attenuator with a " Flat " frequency

response means that " ALL " signals will be applied to the test gear

( Analyser or mW power meter ) will be reduced by the same amount eg A 30dB

attenuation value turning the 200 Watts of the amplifier in to 200mW which is

just about the limit of most spectrum analysers ( an additional 10dB would have

been preferred for safety for the test gear ) but this can be added by using a

standard 2 watt commercial attenuator or by making a similar value home made

attenuator using standard SMD parts and a pcb ( I feel another project coming

up ? ) See the Dual MMIC amp for suitable

attenuators , I said a project would occur .

So after the usual web search , I found a couple of

suppliers ( Anaren &

Aeroflex )

of 100 Watt continuous rated power attenuator chips which were pulse rated at a

higher value , so I set out to design & build a continuously rated

attenuator using standard heatsinks and a " Milled " housing to take

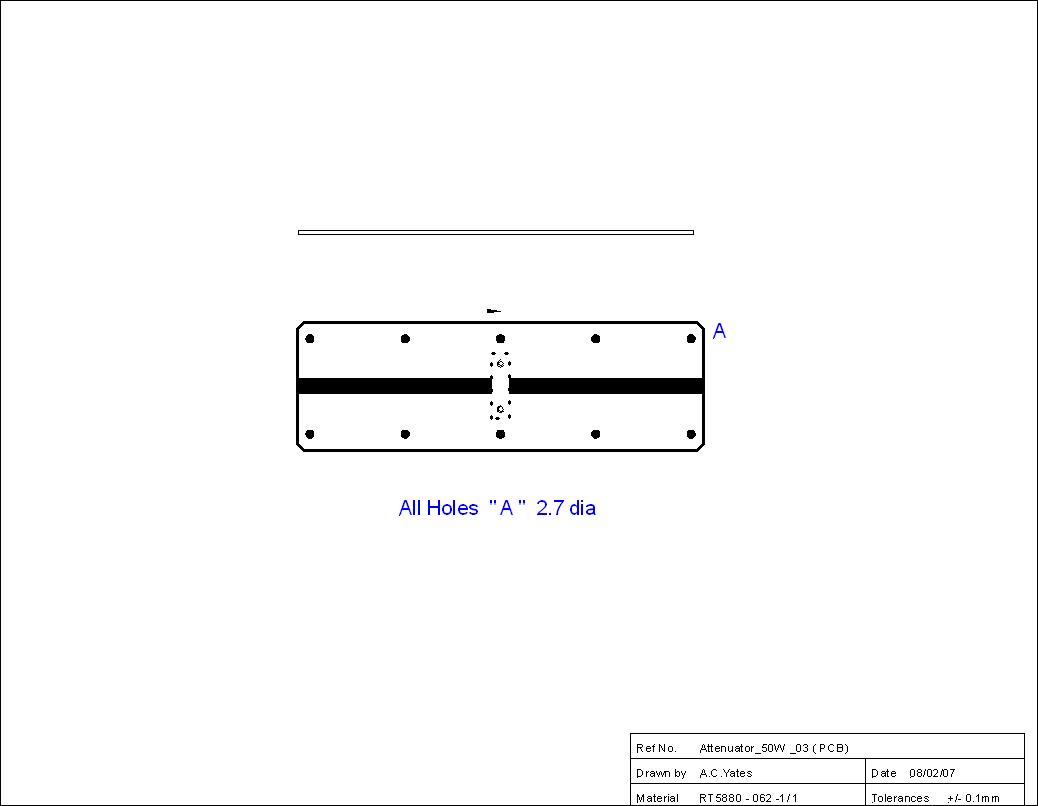

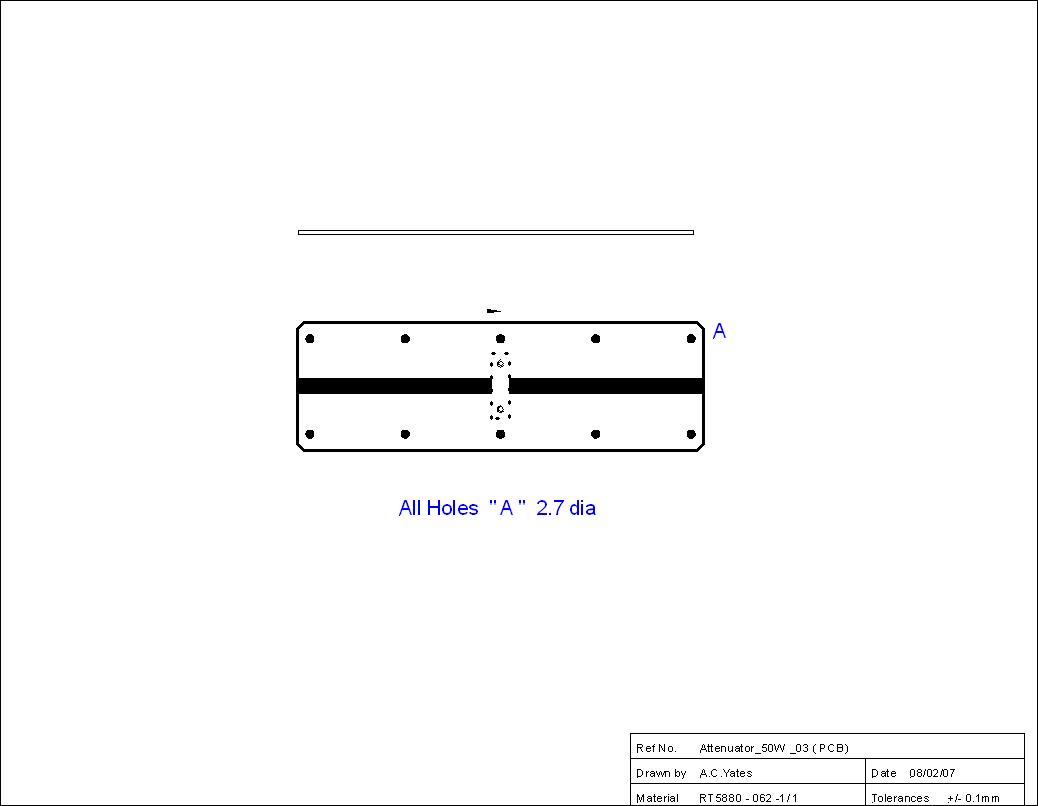

the attenuator and it's PCB . The PCB was modelled using " Microwave

Office " and designed to take the attenuator chip in a cutout. The

response of the real attenuator closely following the modelled values .

The PCB used Rogers RT5880 - 062 - C1/C1 to minimise the

losses up to the designed maximum operating frequency .DO NOT be tempted to redesign the

PCB to use FR4 because above 1GHz especially at High Power it can catch fire

after continuous use due to it's dielectric losses .

The pictures below show the assembled attenuator and also

it's internal construction ,note the use of multiple screws along the PCB is to

minimise any stray reasonances caused by the PCB's groundplane only contacting

the housing at the corners .The connectors used are " N" type and SMA

flanged both with the same fixing centers so that either type could be used (

the SMA can take upto 500 W according to the manufacturer ! )

View of the attenuator chip & PCB in the milled

housing

The holes for the securing the PCB and the power

attenuator " Chip " are all the same size ( to minimise the chance of

damaging the attenuator chip as the insulating layer in the device is "

Beryllium Oxide " ) so the choice of M2.5 " Allen " headed

screws meant that the attenuator chip could be " Torqued " down as

per the manufacturer's instructions as well as using them on the connectors .

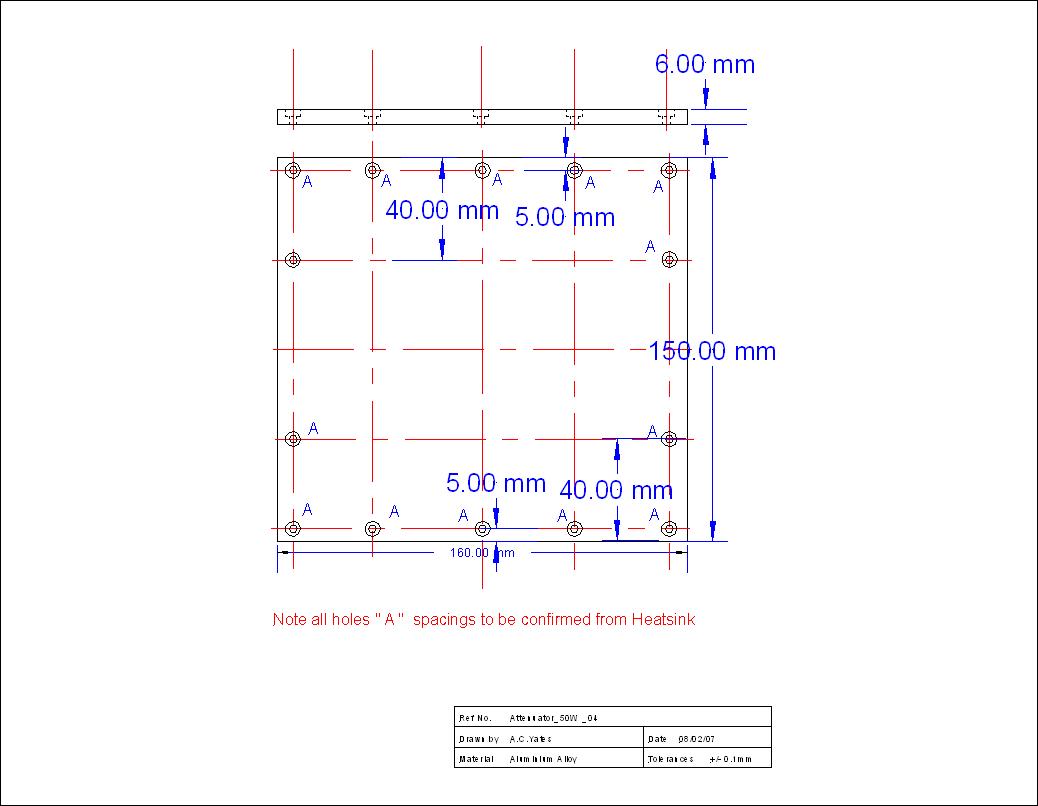

The heatsinks were also secured to the milled housing using " Allen "

headed screws to enable adequate torque to be applied to hold the heatsinks

flat after they had been " skimmed " on a milling machine to ensure a

metal to metal join again to minimise any stray resonances they naturally will

bend due to the stress of the extrusion process used to make them . The design information for choosing the

heatsinks came from ( Link) this

enabled me to check the various suppliers for the relevant heatsinks and

subesquently buy them , a mistake by the supplier ended up with me having two

sets of heatsinks so I made a duplicate attenuator for " work " with

a pair of SMA connectors on it .This was used in testing some student's 3.4 GHz

WiMax amplifiers .( Note since this project was made a safer form of power

attenuator chip using Aluminium Nitride as the insulator has become available

from Anaren )

View of the completed attenuator in use testing my table

top amplifier in the laboratory at work, note the " Homemade " Safety

label to warn people of it's immediate Hazards!

Here are the responses for the attenuator taken at spot

frequencies using the Rhode & Schwarz FSH3 using the internal marker , they

were also checked using a signal generator & power meter hot & cold to

confirm the performance the value beneath the images was taken using a Marconi

2022 & an HP435 Power meter with the attenuator heated using an external

heater ( 2kW fan heater ) to 75deg C case temperature showing only minor

variations from the swept result values .

70MHz attenuation 29.97dB

145MHz attenuation 30.07dB

435MHz attenuation 30.05dB

1260 MHz attenuation 30.12dB

Parts listing for the Attenuator

Item

|

Manufacturer

|

Part Number

|

Supplier

|

Suppliers part No

|

QTY

|

Attenuator

|

Anaren

|

RFP100 - 30AE

|

Anaren

|

RFP100 - 30AE

|

1

|

M2.5 x 6 mm

|

Various

|

- |

FEC

|

883 - 5497

|

20

|

M3.0 x 16 mm

|

Various

|

- |

FEC

|

883 - 5560

|

28

|

M3 washer

|

Various

|

- |

FEC

|

161 - 4001

|

28

|

SMA socket

|

Huber & Suhner

|

23-SMA-50-0-3/111_NE

|

FEC

|

105 - 6376

|

1

|

N socket

|

Huber & Suhner

|

23-N-50-0-30/133_NE

|

FC Lane

|

23-N-50-0-30/133_NE

|

1

|

Heatsink

|

Marston

|

938SP

|

FEC

|

526 - 794

|

2

|

Aluminium bar

|

170 x 170 x

46 mm

|

- |

Various

|

|

1

|

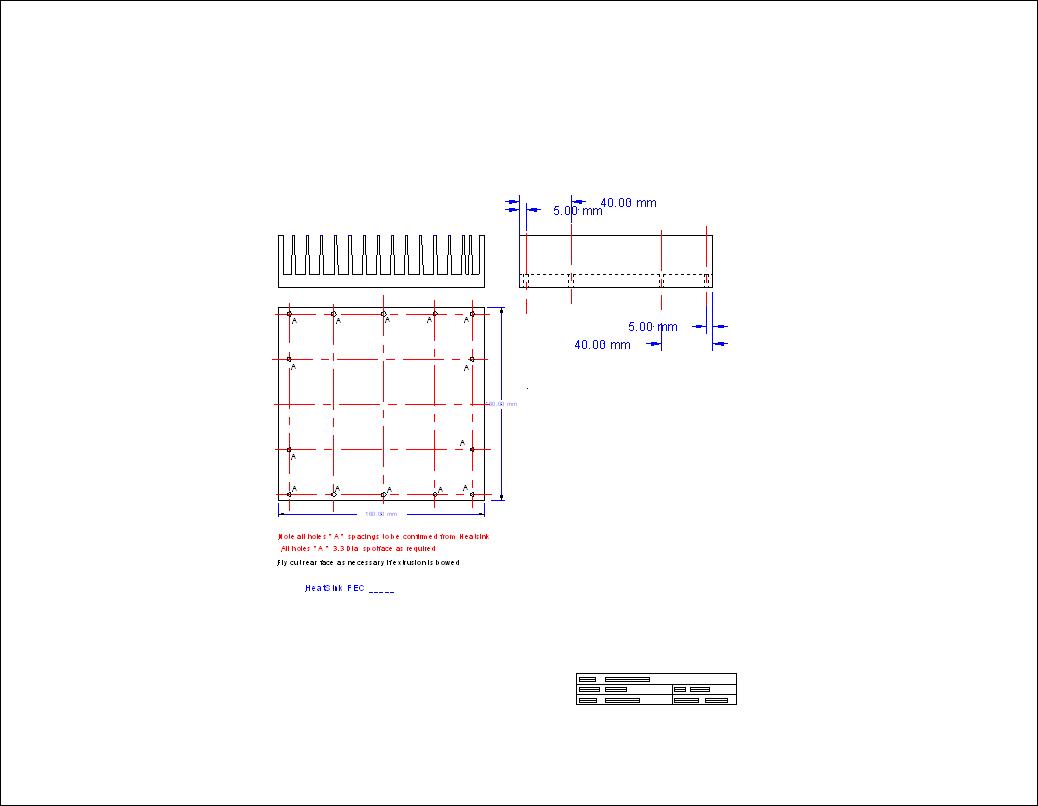

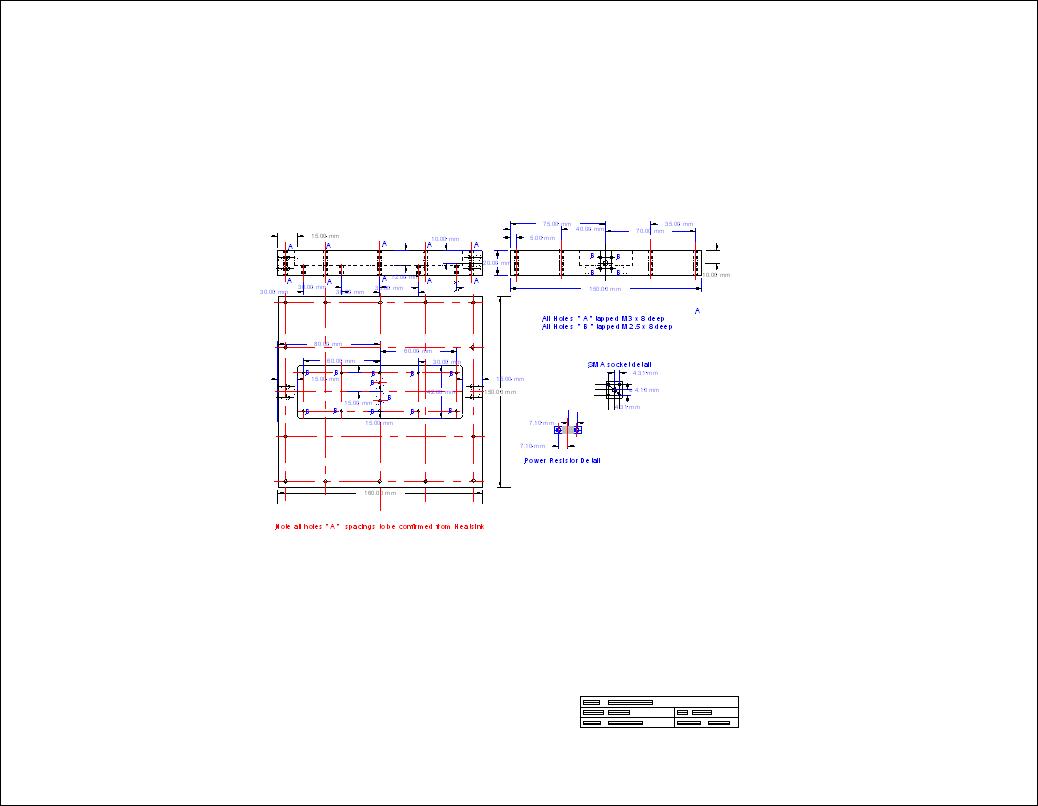

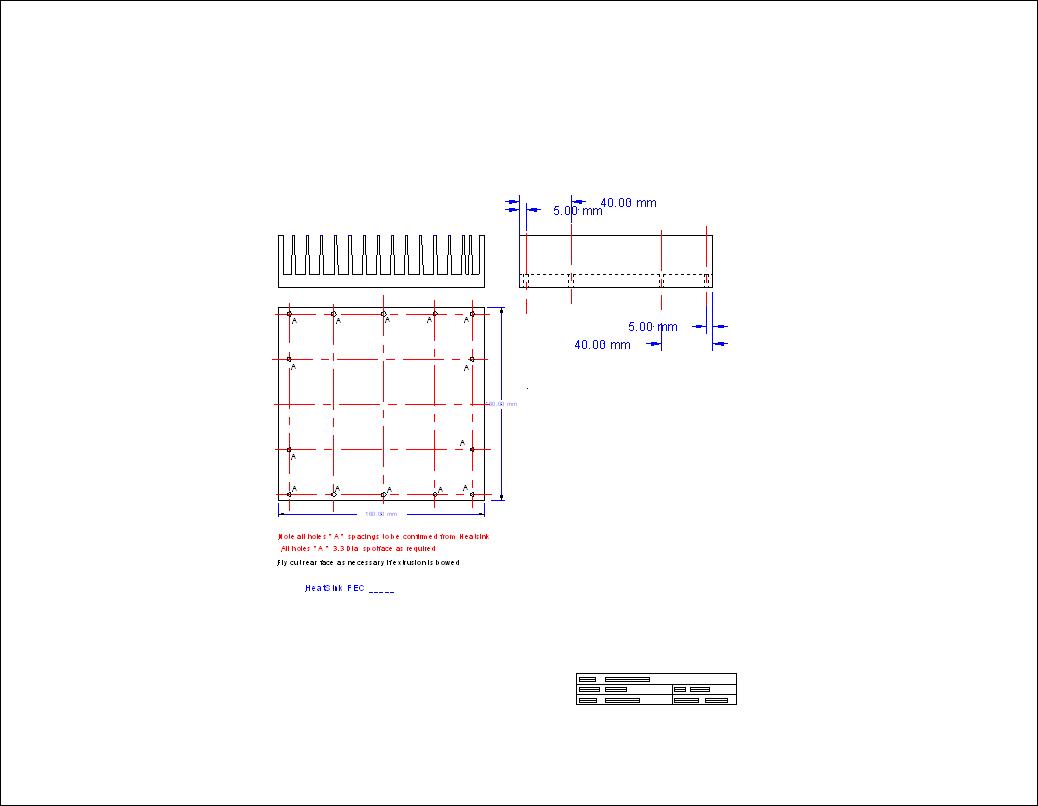

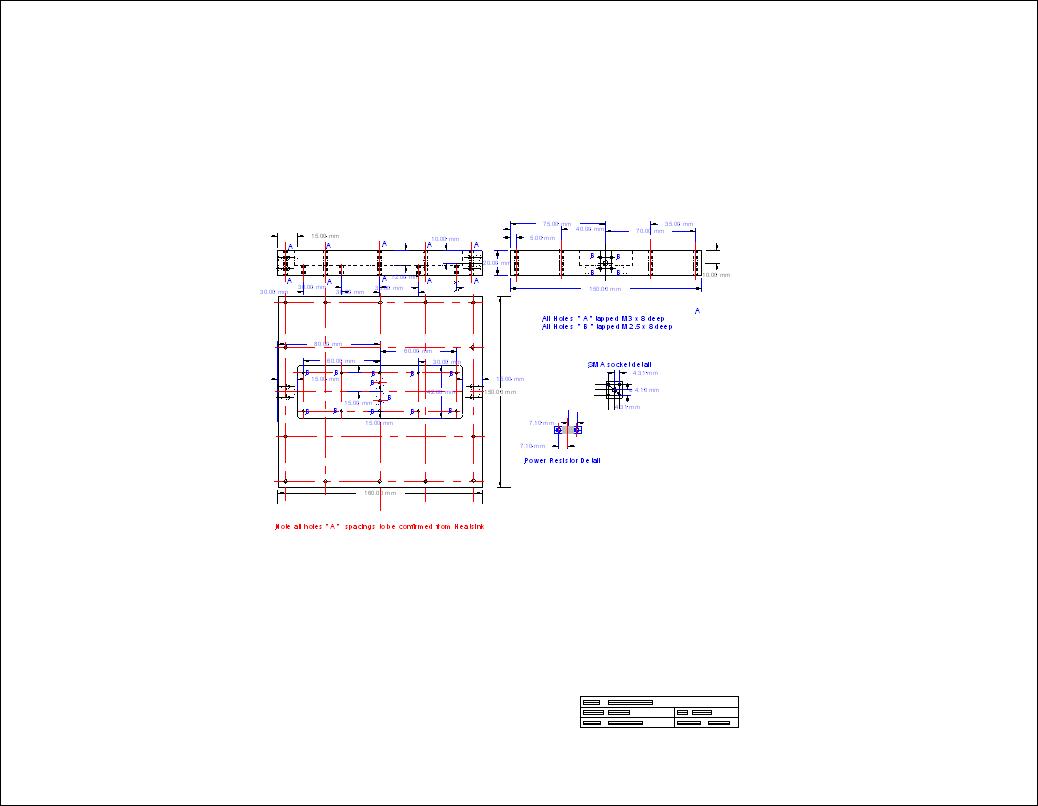

The CAD drawings of the attenuator PCB , housing &

heatsink are all available as PDF' below

The printer ready PDF's for the drawings

General assembly drawing

Heatsink drawing

Module Housing

Printed Circuit board

A 50 Watt version using one heatsink has also been

constructed for a fellow radio amateur see below for the drawings

The printer ready PDF's for the drawings

General Assembly

Heatsink drawing

Module Housing

Printed Circuit board

Housing Cover

As an after thought I decided to see what was on the

commercial market and found similar designs were available from

Bird

Rf Products and several other manufacturers although the physical size was

the same , although the styling was a little different .

Back to Amateur Radio Projects

This page last updated 04 May 2018