Simple Microwave Office

Projects

These projects are aimed to give the novice an idea on

how to lay out various simple type of circuit , the design criteria for your

project will have already been decided for you , these projects are designed to

show you the various PRACTICAL implementations of your project from the basic

circuit which you would have used for lower frequency work ( as part of your

course ) both for passive & active designs .

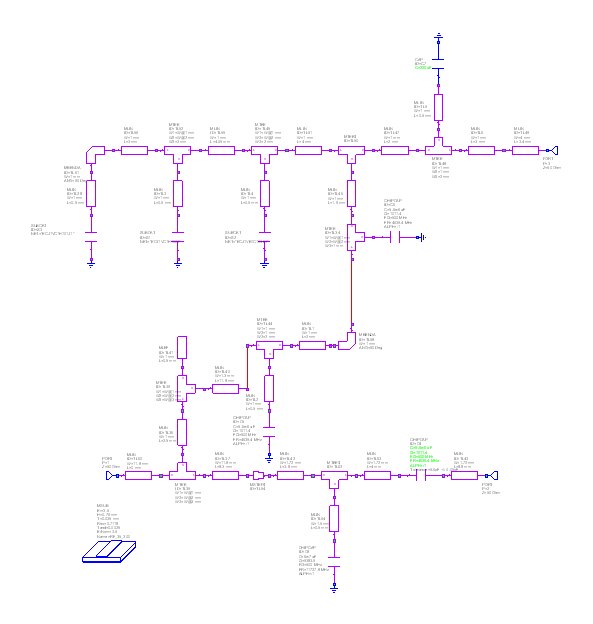

Simple Band pass filter for

7.5 GHz using Microstriplines

This project illustrates the use of transmission lines

of variable widths being combined to produce a band pass filter this was used

in a forward scatter radar transmitter by the MISL group . It also high lights

the need for accurate modelling of ALL the relevant components , the

differences between the two circuit's responses highlights the need to be fully

aware of even the simplest of designs, the only difference being the addition

of step transitions between the capacitive & inductive striplines , the

lengths & widths of the actual striplines being the same in BOTH circuits ,

designing without these transitions results in a center frequency error of

about 10% , this was born out by constructing the filter with the step

transitions missing then testing it on a Network analyser , and comparing the

real world design with both modelled results ! The use of the step transition

is advisable when there is more than about a 25% variation in the width of

adjoining striplines .

Basic MWO circuit (

microstrip elements )

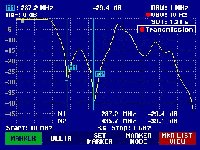

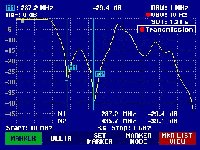

S11 , S21 Responses for

the MWO Basic circuit

Revised MWO circuit (

with simple microstrip & junctions)

S11 , S21 Responses for

the revised circuit

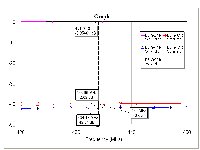

Comparison of Basic &

Revised circuits

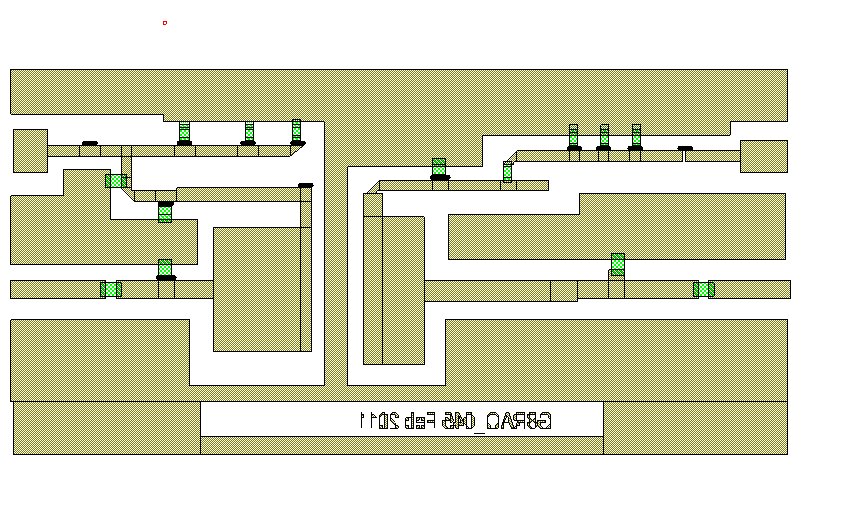

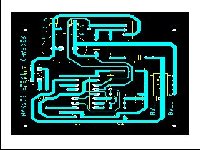

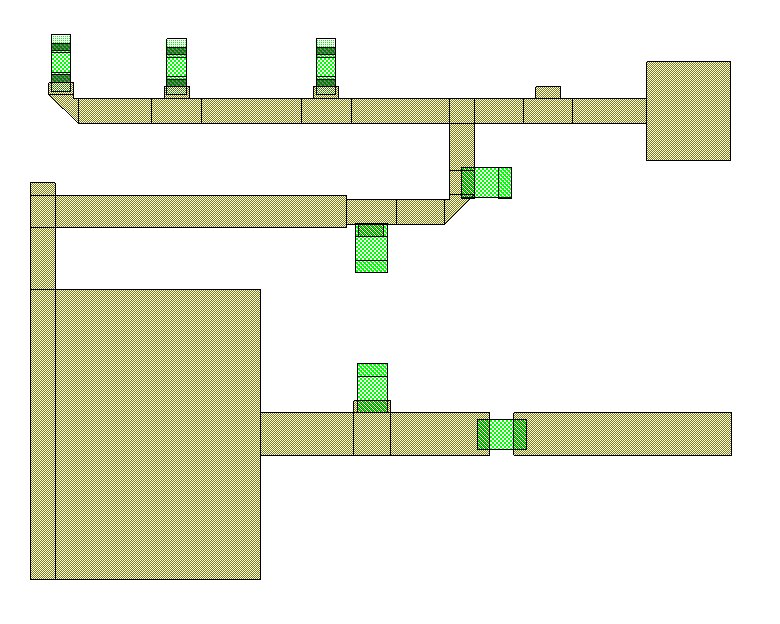

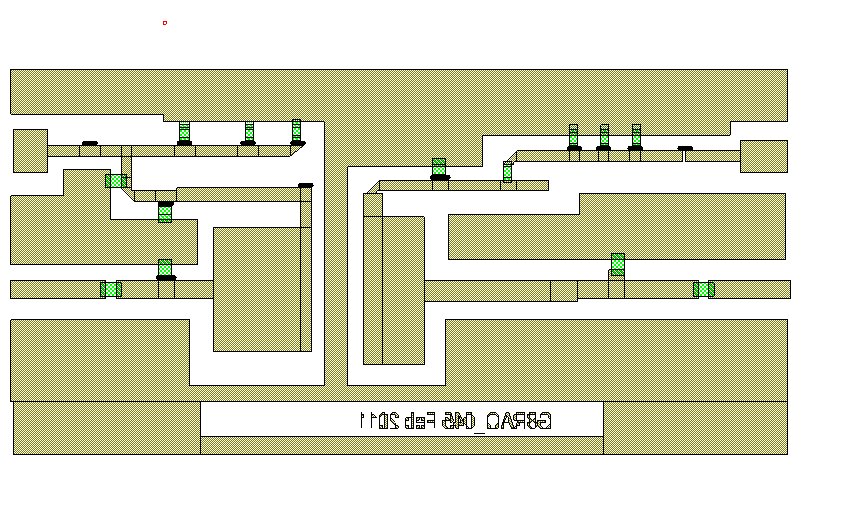

MWO Artwork for the

Revised filter

CAD generated

Artwork ( Photo - negative )

VNA Plot of real

filter

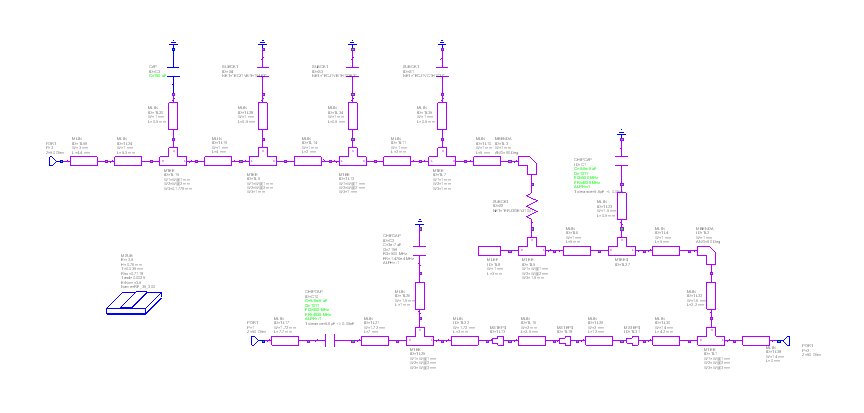

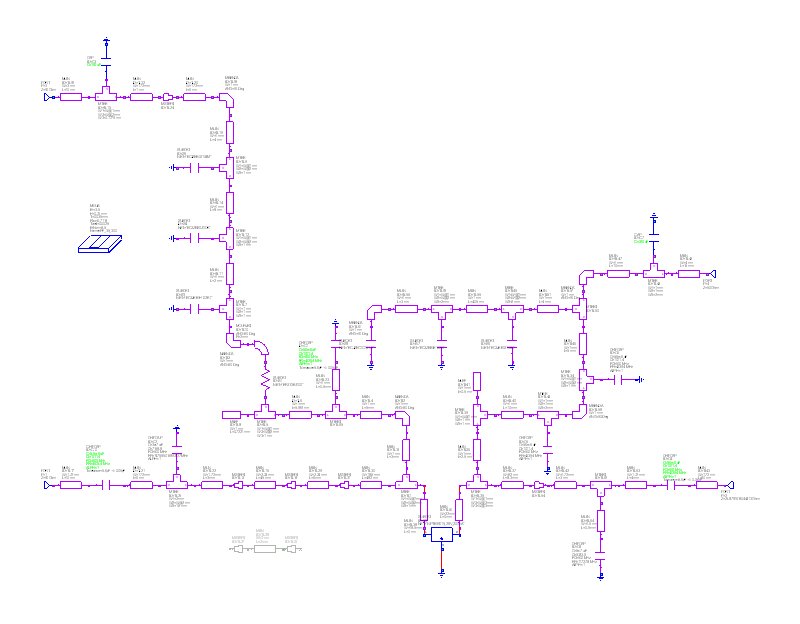

Dual MMIC Amplifier for 1 to 4

GHz

This project was conceived to provide a tried &

tested amplifier for both my amateur radio projects and also to give to

students as a basic building block to drive RF power devices to around about

the 1 watt level ( from the tracking generators in the Spectrum & Vector

Network Analysers ) for either Wlan or Wimax power amplifier projects. It was

designed to be as flexible in nature so is two stages of SOT89 or MP86 package

MMIC's with provision for attenuators to set the overall stage gain / allow

some protection of the MMIC's in a research & teaching lab environment.

Both Minicircuits

& Hittite have

a range of suitable MMIC amplifiers , the student just has to choose the

suitable combination for Frequency response , Power output & Gain

required for their project , the attenuators are made up using "

Preferred Value " resistors so their attenuation is not " Whole dB's

" the 1dB attenuator on the output ensures the following stage "

see's a resistive source at all frequencies ", the use of twin resistors

for the shunt element's improves the return loss of the attenuator as well as

increasing the power dissipation at that point in the circuit.The circuit is

modelled as usual using Microwave Office

from AWR , but could just as easily be modelled using the

Ansoft Designer SV

package which is currently free or any other suitable RF modeling

package.The circuit uses an attenuator on the input to ensure stability given

the high gain of the MMIC and also to provide a resistive load to any preceding

stage eg filter . The stages will be fed from a small voltage regulator to

ensure the gain remains stable in a lab environment ( people rarely set bench

top power supplies to the same value each time they use them ) the amplifier

module was designed to fit in a standard commercial tinplate case measuring 50

x 25 x15 mm using a pair of SMA sockets for input / output connections with the

upper & lower groundplanes soldered to the case to provide a low inductance

grounding ,the earth planes nearer to the microstriplines were " Tied

" together using my traditional technique of 0.5 mm holes with a single

strand of 0.2 mm wire from ordinary instrument wire to suck the solder in by

capillary action , the same is applied to the grounding of the tabs on the

MMIC's to ensure a low thermal path as well as good RF earthing. The circuit

was laid out with Microwave Office using

the package's component libraries for ALL the parts as listed in

the various supplier's catalogues to ensure that the parts chosen were freely

available ( Preferably from more than one supplier ) with the full

manufacturer's part no. checked in the Microwave

Office Online component libraries or downloaded from the

manufacturer's own websites , as a result of laying out the circuit with all

the relevant tracks junctions & components it's quite easy to see ALL the

elements involved in just a simple two stage amplifier ( It fills an A3 page ),

the Voltage regulator circuit was added later in the CAD layout of the board

after it had been generated in Microwave Office

using the relevant layout tools this means that you

can see the effects of the grounding you add as you create a full PCB artwork

remembering to ADD all the relevant text to aid testing & inspection of the

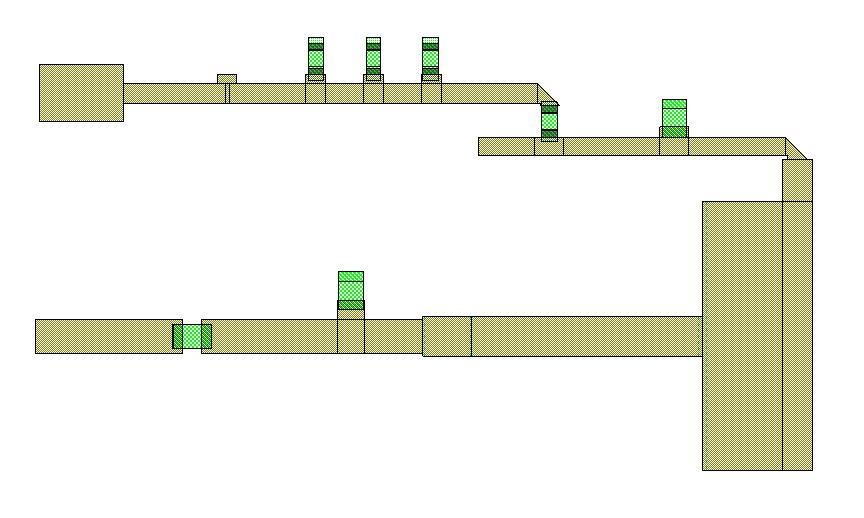

completed project. Having created the schematic in the modelling package the

design is then transferred to a basic layout this only has components &

microstrip on it the ground plane and board outline together with the relevant

text to be etched on the Top copper layer are now added , this enables you to

check that any grounding alongside microstripline does not turn into "

Coplanar stripline " shold you need to extend tracks up to the edge of the

board to fit it in a standard box then these can easily be re - modelled at

this stage before committing the design to production . The

stages in reaching the completed artwork ( including the " Mirroring

" to produce a contact print ) are detailed in the modelling package but

the instructions are often buried several layers down in the help files . This

is a simple stage by stage set of instructions to enable anybody starting off

using the modelling packages to get an artwork out ready for exposing a Photo -

Sensitve PCB substrate .

The simple " Step by Step " instructions

for using Microwave Office for these projects are

listed below

Lay out your circuit using the relevant components &

symbols from the MWO library or download them from the manufacturer's sites ,if

your chosen component has to be loaded as a subcircuit using just the" S2P

" data from the manufacturer's website then there is a work around to get

the package , simply use the MWO website to find a device with the same package

as the device you have only the " S2P" for simply add this to your

drawing at schematic level as a " Floating " component then when you

go to the layout place it where you require it , this is not perfect but will

at least enable you to get an artwork with the right size component footprint ,

it will also show up correctly in the 3D visualisation .

Then add all the graphs you think you will need together

with any text, when you have your desired amplifier completed at schematic

level .

Then convert it to a layout using the relevant part of

the program , you will end up with a " Rat's Nest " of all the parts

don't forget if you have had to add a device for it's footprint to place it in

the correct location at this stage .

Now lay these out as per your circuit diagram , the

individual elements in the layout are highlighted as you move them ( if you

wish to check back to the schematic you will see them highlighted accordingly

in Green ). Then using the select all the items you wish to place , then from

the tool bar using the " Snap

Together " tool you can automatically place all the tracks

& components that are highlighted , this saves a lot of time laying out the

parts to join accurately , you may also use this tool if you modify the layout

, for instance to fit a standard sized case , don't forget to go back to the

schematic page & redo the simulation eg when you have bent a trace to fit (

eg when using " MTRACE2 " ) or you have

added the top side groundplane which is not

automatically generated by the package to enable

decoupling capacitors to be grounded you may also need to add holes to make

connections through the board to the main groundplane , the spacing of these

holes in general should be less than L/4 to ensure no stray resonant currents

build up in the top side ground plane with respect to the lower groundplane .

With the microstripline used to go to the ports of the circuit it is advisable

to allow for about 10 mm of system impedance ( 50 R ) for the legs of the edge

transition SMA connectors , don't forget to buy the right type for the

thickness & spacing to suit your board height & transmission line width

!

An

interesting point to remember when using these edge transition connectors is

that the legs that fit over the PCB are in fact protruding from the groundplane

( Body of the SMA ) and at certain frequencies these may be coupled in to the

transmission line causing problems when the are 1/4 wavelength long they become

Monopole aerials this happened on a wideband

aerial for 12 - 14 GHz !

Then add a shape for the housing you intend

using using the " Layout

editor " ( Toolbar at the bottom of the screen or drop

down menu ) to " Add

Shape " this will put a shape up coloured in as

" Error " initially .

Then by using the "

Shape Properties " command you

can change it to " Board

Outline ", then you can repeat the " Add shape

" routine to ADD the groundplane as you require

" Copper Layer

" being chosen . By returning to the schematic part of the program

you can see the effects on the circuit of adding the grounding areas changing

line lengths to fit the board outline etc , Text can be added using the text

editor on the taskbar ( The same way as you added text to you circuit &

graphs earlier ).

Then when you have your completed design laid out copy

the whole layout ( if more than one layer then check each one ) & mirror it

and place it on the page below the " Normal " layout also you are

advised to label the mirrored artwork with the relevant wording ( "

Mirrored Artwork this side to copper " ) and in the case of a multi -

layered design add a reference point " A " on ALL layers to ensure

the correct aliginment , you are now ready to export your completed layout in

to one of the CAD packages mentioned on this website , exporting it as a

" Flat DXF

" is the easiest option , this is then read in to the CAD package (

You will have to set the drawing defaults up at this stage see the

relevant webpage

) .

Then you can finally colour the relevant areas of you

layout in according to whether you require a photo positive or photo negative

artwork you will need to choose the approriate colours for all the lines in the

drawing otherwise the individual shapes drawn will be just that NOT joined up

tracks !

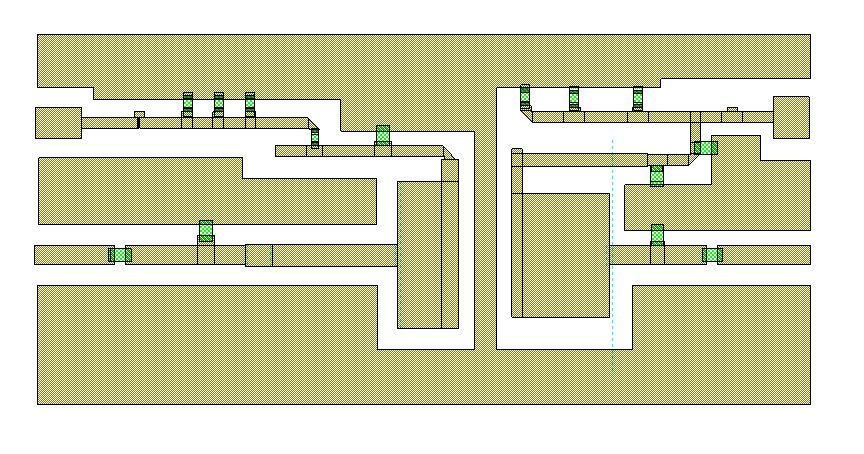

The Circuit design and Graph of modelled results

The PCB Layouts are shown in stages ,the only

difference between the artworks is the ground has been added using the Layout

editor in MWO for the second PCB layout and the

mirrored artwork has been added in the second layout.

The CAD artwork this is derived from second layout above

, the DXF exported from MWO with the normal &

mirrored layouts ready to fill to create the " Contact " print which

can also be copied in to a word document .Note you may have to select the

appropriate layer ( Top Copper ) during the exporting of the DXF as the view

includes the component outlines .

Alternative attenuators for gain setting

The Finished module

Parts Listing for the Module ( Includes all gain setting

values )

| Item |

Manufacturer |

Part No. |

Supplier |

Supplier's Part No

|

QTY |

| 78M08 |

Various |

78M08ACDT |

Farnell

|

516 - 4929 |

1 |

| GALI5 |

Minicircuits

|

GALI - 5 |

Minicircuits

|

GALI - 5+

|

1 |

| GVA84 |

Minicircuits |

GVA-84 |

Minicircuits |

GVA - 84+

|

1 |

| 1R2 " 0603

" |

Various |

|

Various

|

|

2 |

| 5R6 " 0603

" |

Various |

|

Various |

|

1 |

| 12R " 0603

" |

Various

|

|

Various

|

|

1 |

| 18R " 0603

" |

Various

|

|

Various

|

|

1 |

| 33R " 0603

" |

Various

|

|

Various

|

|

1 |

| 39R " 0603

" |

Various

|

|

Various

|

|

1 |

| 180R " 0603

" |

Various

|

|

Various

|

|

4 |

| 330R " 0603

" |

Various

|

|

Various

|

|

4 |

| 390R " 0603

" |

Various

|

|

Various

|

|

4 |

| 680R " 0603

" |

Various

|

|

Various

|

|

4 |

| 820R " 0603

" |

Various

|

|

Various

|

|

4 |

| 1K8 " 0603

" |

Various

|

|

Various

|

|

4 |

| 100pF " 0603 " |

Various

|

|

Various

|

|

6 |

| 1nF " 0603

" |

Various

|

|

Various

|

|

2 |

| 100nF " 0603

" |

Various

|

|

Various

|

|

3 |

| SMA Socket |

Various

|

|

Farnell |

105 - 6374 |

2 |

| 10nH |

Coilcraft

|

1606 - 9 - LB

|

Coilcraft

|

1606 - 9 - LB

|

2 |

| 50 x 25 x 15

case |

Perancea |

PFL - 2 - T |

Farnell

|

118 - 1374 |

2 |

Single stage Amplifier

for 3.4 - 3.8 GHz Wlan band using a GaN Fet

This module is designed to produce about +30 to +33dBm

using the NPTB0004 for driving the output stage in a Doherty amplifier using a

pair of NPT35015 GaN Fets , it uses the "Standard " GaN Fet bias

power supply module

Versatile Bias

Regulator for GaN Fets mounted on the case of the amplifier module,

although with a little effort it could be redrawn to fit on the main PCB on one

of the large ground areas ( future work ? )

Circuit of 30dBm Wlan Amplifier

Graph of Amplifier responses ( S11, S21

& S22 )

Artwork of 30dBm Wlan Amplifier

Mirrored Artwork ( Photo - negative

)

3D View of PCB ( MWO )

15 Watt Single stage Amplifier for

3.4 - 3.8 GHz Wlan band using a NPT35015 GaN Fet

When you design your circuit using a modelling package

you should be aware of the needs of the physical implementation of your design

so that to design this amplifier the starting point was the manufacturer's test

circuit for the device ( LINK )

this technique applies to ALL circuit modelling packages but as I'm used to

using Microwave office I'll give more detailed instructions for this package (

I've also tried it out on the free " Designer SV " package at home )

this is the design for a 15 - 20 Watt broadband amplifier using the GaN fets

available from Nitronex together with it's 2

Watt driver the 10 Watt amplifier uses the NPTB35015 & the Driver uses the

NPTB0004B the circuits are designed to be wide band with as flat a frequency

response as practicable so the use of " Tunable components " is

avoided ,the various elements are chosen from the library of the modelling

package or the individual manufacturer's websites & inserted as

sub-circuits using the software for the components which are not contained in

the relevant libraries , Micro-strip elements & board parameters are

usually in the manufacturer's libraries in the package ,but you often have to

use " Online " libraries for upto date data for individual components

.Some of the modelling packages have an in built optimisation tool to tune the

design from your layout , whilst this may save time for some users it must be

noted that this is NOT " Intelligent " it will only work within the

parameters that you the designer specifies ( You can easily put

one track down the middle of another ) .The way the lengths & widths of the

individual elements are written will enable the software to do the optimisation

but the designer will need to specify the ALL the relevant limits , so by

carefully adding in ALL the elements needed to replicate the layout of the

manufacturer's test board it is possible to reproduce it , however there are

some " Tricks " to laying out the board such that the assembly can be

done with minimum recourse to moving parts to obtain the required performance ,

for instance it is easy to model a shunt capacitor from a transmission line to

earth but actually placing it to sub millimeter accuracy by HAND is another

problem , so why not use the modelling software to help you , by using a

microwave junction ( Tee or Cross ) you can add a short < 0.5mm track equal

to the width of the shunt element , this will produce a definite location on

the transmission line to locate it , ( the beauty of this is the software also

knows it's here ! ) so you should get the results you expect . Also as you

design the bias tee's ( Gate & Drain ) you should ensure that there are

pads of fixed width equal to the transistors connection to ensure that the

optimisation tool does not produce tracks that are too narrow to support the

device or put them up the middle of the transmission line ( you have to specify

the line lengths correctly just look at the circuits below to see how to do it

) the components in the bias tee's will require spacing to permit the soldering

of individual components so tracks of a minimum length should be included in

the design , again it is you the designer who knows the minimum spacing for

your soldering skills . If you do not have the footprint / layout from the

modelling package's library ,there is a work around whereby you can include a

device with the footprint of your chosen device somewhere on the circuit ( BUT

NOT connected to it ) this is to enable you to place the tracks at the correct

spacing to enable the final layout to be produced before exporting it to

generate the artwork , you could always learn how to create component layouts

in an appropriate CAD program then import them as the program designer's intend

you to ( but then that's another story !) . The circuit parts shown below have

all the relevant information set in their parameters each limit is explained

for each circuit together with the final layout of the completed board , this

will just need mirroring in the layout editor to produce the contact print as

most CAD packages do not mirror the text you have included on your design put

it in the layout in your modelling package !

The Amplifier Input & Gate bias circuit

The layout of the input circuit

The circuit as initially modelled , before the added

copper pads for the top groundplane which when added are shown in a different

colour to the modelled microstripline , these will of course all end up the

same colour when you do the CAD work , to complete the artwork according to

whether it's photo - Positive or Negative artwork required .

The Amplifier output Circuit & Drain supply

The layout of the output circuit

The combined circuits are shown below ( note this was

before the revised circuits for the bias networks were used to ease the placing

of shunt components )

The Completed layout showing all the relevant features

combined this is before any ( optional ) text has been added to identify the

connections or " name " the board , this being done by removing the

large areas of groundplane and replacing them with smaller areas around the

text along with any fixing holes neccesary to secure the board to it's housing

/ heatsink .

The mirrored artwork is now ready to print out for a

" Contact " printed PCB when exported via you CAD package ( Currently

I use either

Quickcad

or it's replacement

Autosketch

)

The final " Mirrored " artwork ( with text )

from Microwave Office prior to exporting to the CAD package

Back to RF Design For Students

This page last updated 16th May 2013