Basic Design

Notes for Printed Circuit Boards For RF Circuits

Before creating your PCB you will need to choose

ALL the components needed to fit on to your pcb , remember if you

intend to use the edge transition coaxial connectors that they have different

sizes of leg spacing between the center conductor & the coax outer ( legs )

this will influence the choice of substrate to be used ,in order to design to

avoid shorting out the connector / coaxial cable because you've chosen the

wrong parameters ( Dk & thickness )! I will have fully worked examples of

High Pass Filter & RF Low Noise Amplifiers on my Amateur Radio projects

pages shortly .

If you are creating a multi layer PCB it is advisable to

put alignment & reference marks on each layer so that correct alignment of

the layers can be achieved , the use of a " board outline " option

can add an unwanted single turn loop around your circuit (

you've just added a single turn transformer secondary

), if your design requires more than two layers then to assemble the

composite you will have to think more about the mechanics of this assembly.

Accurately placed pads that can be drilled in each PCB for non metallic

fasteners ( eg Nylon Screws ) to provide the alignment is a relatively easy

process ,this also means that with the correct spacing of the screws you can

ensure that the layers are spaced as per your design and not have any air gaps

to change the dielectric layer in the structure as it is flexed during testing

/ handling . Obviously the size of pad should be less than the thread diameter

of the fastener to be used so that ALL of the metal can be

removed by the drilling out otherwise the metal pad will affect the designed

radiation pattern in the case of an aerial . For a fully detailed project using

Microwave Office with all the stages for

design & fabrication follow this link ( Dual MMIC amplifier)

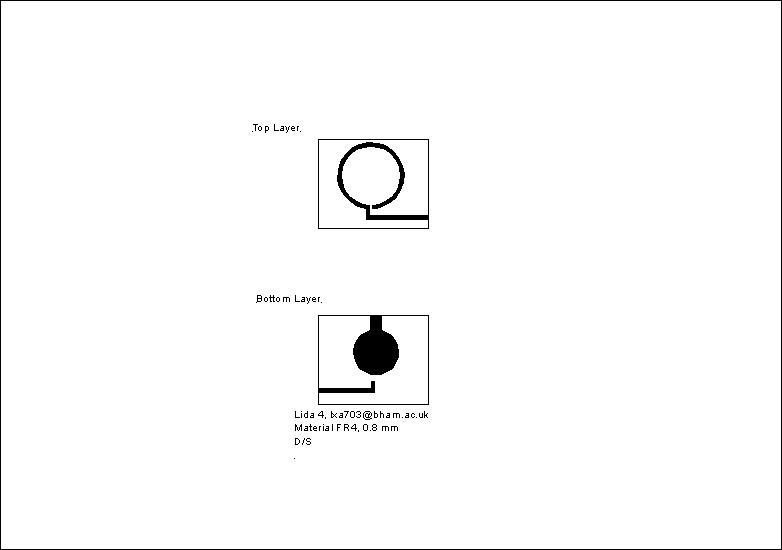

Having created your PCB artwork(s) using the appropriate

software , it is neccesary to printout the artwork(s) ready to produce the pcb

, the process used is to make a contact print for each layer of the PCB ,

remember the " Top " layer of a double sided PCB will need to be

mirrored in order to maintain the printed layer in contact with the photo -

sensitive layer on the PCB conductor. Each layer of artwork should be labelled

with the relevant contact details , substrate material & layer you should

also incorporate cutting symbols at the corners of the PCB as the fine lines

created by the software for board outlines often get etched away or need to be

removed for electrical reasons eg on an aerial design , the easiest way is to

use the " + " symbol at the corners of your pcb . If the PCB is to be

single sided with a ground plane then again this information should be included

on the printout eg " D/S with groundplane " although the ground plane

may not be needed to be printed unless you have clearance holes in it

. With microstriplines close to the edge of the pcb

you have designed if it is going to be cased then you should allow at least 3

track widths from the edge of the microstrip to avoid interaction between the

line & the case ( A Coplanar wave guide could be formed otherwise ) unless

you are using " Shunt " elements ( eg Capacitors for matching ) as

part of your design.

When designing with either Microwave Office , ADS or CST Microwave you should

be aware of the following requirements needed to create an artwork .

If you are using " Pre Coated FR4 " as the PCB

material you will need to create a " Photo Positive " master however

if you intend to use " Duroid " or a similar uncoated substrate then

the process to coat this material is different , in that a " Photo

Negative " artwork is required and you will need to ensure you design your

layout accordingly .In industry your artwork would normally be exported to a

draughtsman to further process ,Microwave

Office 2006 has a DXF output

option , however Microwave

Office 2007 or later also has a Gerber Output function in

it to produce artworks using a laser plotter . CST

Microwave currently only supports outputs in DXF for artworks (

the BMP option is only 96 DPI good enough for putting your design in to a

document but NOT artwork quality !) ADS currently only supports

outputs in DXF.

Should your pcb need to be mounted in a custom housing the option

of " Export in DXF " from your chosen PCB package should be used to

enable you to design a housing using one of the many CAD packages available

.

The currently

available software for POST GRADUATES &

RESEARCH STAFF from Comms Group is Quickcad

& Autosketch to convert the files

from DXF format to generate the artwork then save it as a .CAD / DWG or

equivalent format .

For

ALL Taught Course Students there is

a choice of a work around using the packages currently available in the lab

N218 using Autosketch

to import the DXF then save it

(SKF) then open it using to

fill the outlines etc OR you can use Autodesk's " AUTOCAD 2010 " using a downloadable copy

available to students by contacting Autodesk directly but this cannot be used

on EECE PC's .

Please follow one

of the links for detailed instructions .

For " Taught

Course Students " If you have any questions about the

software you are using to create your PCB then you should ask your SUPERVISOR first ,not the support staff as they

may not use it on a regular basis .

A typical Student's artwork

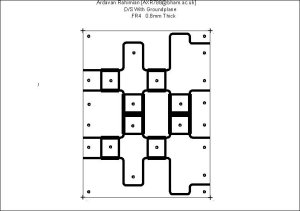

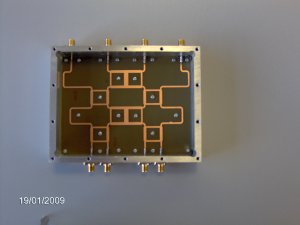

Here is a more complicated design created using

Microwave Office for a " Butler Matrix " the fine lines for the board

outline are often etched away during the production of the board so the use of

" + " symbol to define the corners is advisable , also note

the fixing pads for the mounting screws as the completed board is to be housed

in a metal enclosure these pads are SMALLER in diameter than the screw thread

so that when they are drilled out there will be no metal left to affect the

design ( IF you use NYLON screws to secure the board ) or you can use metal

screws with a possible change in performance ( You could always model the screw

! )

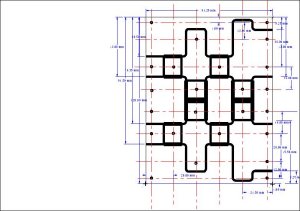

The same PCB artwork with the centre lines used to lay

out the pads accurately , this drawing is used to construct the housing around

the PCB

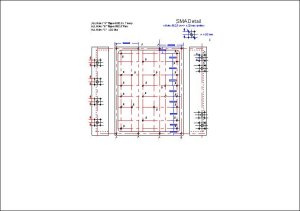

The drawing for housing the PCB.

The completed PCB ready to test before fitting in the

housing .

The finished article , the PCB in it's

housing

Having finally arrived at your completed

artwork it is advisable to Email the person responsible for making your PCBs

both of the quantity and any specific delivery date , it is also advisable to

include your contact details on the artwork ( University Email address / phone

number ). But , please bear in mind , there is a

typical lead time of up to 5 working

days between printing out your artwork together with handing in

the unetched substrate & receiving an etched PCB .This is because if other

members of staff have to cover the " normal " person , should this be

the case then information can then be forwarded accordingly , also stick on

" Post - it's " have a habit of blowing away or otherwise getting

lost , so please use Email!

For ALL " Taught Course " ( BEng , MEng &

MSc ) students this is Robert Davies R.K.Davies@bham.ac.uk he may then pass you on to one of

his technicians .

For MRes , MPhil & PhD in Comms group this is Alan

Yates A.C.Yates@bham.ac.uk

Back to RF Design For Students

This page last updated 15th Jul

2015